Conical Bottom Tanks

Conical bottom tanks (OTCB & ICB) are available in seamless molded one piece units from either virgin high density crosslink or FDA-compliant linear polyethylene.

Why a Conical Bottom Tank?

A funnel shaped conical plastic bottom with 30° or 45° slope is molded-in as are gallon markers and access openings. They have more resistance to corrosion and chemicals than fiberglass, stainless or mild steel. Wall thickness conforms to ASTM D-1998 standards for liquid containment.

— Excellent low temperature resistance

— UV stabilized against degradation

— Available in natural color or optional blue, green, yellow or black

Common Use

Conical bottom plastic tanks are often used in process applications, because of their ability to drain completely and efficiently.

Large Conical Bottom Storage Tank Specifications

| Model Number |

CAD | Capacity (US Gals) |

Slope (degrees) |

Dimensions (in) | Weight(lbs) Linear & Crosslink Polyethylene |

Stand Drawing |

Stand Weight (lbs) |

Access Opening (in) |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Diameter | Length | 1.5 Sp. G | 1.9 Sp. G | 2.2 Sp. G | |||||||

| OTCB300 | CAD | 300 | 45 | 49 | 88 | N/A | 115 | 133 | ICS300 | 210 | Open Top |

| APCB560 | CAD | 560 | 30 | 54 | 90 | N/A | 180 | N/A | ICS560 | 215 | 16 |

| OTCB600 | CAD | 600 | 45 | 57 | 105 | N/A | 180 | 208 | ICS600 | 260 | Open Top |

| ICB1100 | CAD | 1100 | 45 | 69 | 116 | 173 | 218 | 255 | ICS1100 | 350 | 16 |

| OTCB1100 | CAD | 1100 | 45 | 69 | 109 | 173 | 218 | 255 | ICS1100 | 350 | Open Top |

| ICB1575 | CAD | 1575 | 45 | 86 | 121 | 325 | 450 | 521 | ICS1575 | 440 | 16 |

| ICB2200 | CAD | 2200 | 30 | 96 | 119 | 500 | 600 | 695 | ICS2200 | 440 | 24 Top Hinged |

| ICB2600 | CAD | 2600 | 45 | 86 | 159 | 540 | 700 | 811 | ICS2600 | 440 | 16 |

| ICB3000 | CAD | 3000 | 30 | 90 | 154 | 620 | 825 | 955 | ICS3000 | 450 | 16 |

| ICB4200 | CAD | 4200 | 30 | 96 | 177 | 850 | 1000 | 1158 | ICS4200 | 550 | 16 |

| ICB6000 | CAD | 6000 | 30 | 143 | 162 | 1800 | 1900 | 2200 | ICS6000 | 3200 | 24 Top Hinged |

| ICB8000 | CAD | 8000 | 30 | 143 | 190 | 2000 | 2600 | 3000 | ICS8000 | 3200 | 24 Top Hinged |

Small Conical Bottom Storage Tank

A funnel shaped conical bottom with 45-degree slope is molded-in allowing for complete drainage of your tank’s contents. These are often referred to as full drain, inductor, or mixing tanks. A variety of top access openings are available. These small cone bottom tanks are available with all polyethylene conical support stands.

— 7″ cap is typical

— optional 11″ cap

— 16″ lever-locking cover

— Or special fume tight access openings

Small Conical Bottom Tank Specifications

| Model Number |

CAD | Capacity (US Gals) |

Slope (degrees) |

Dimensions (in) | Sp.G. |

Wgt. |

Sp.G. |

Wgt. |

Sp.G. |

Wgt. |

Stand Drawing |

Stand Weight |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Diameter | Height | ||||||||||||

| ICB60 | CAD | 60 | 45 | 35 | 46 | 1.5 | 29 | 1.9 | 29 | 2.2 | 29 | APCS-35 | 77 |

| ICB100 | CAD | 100 | 45 | 35 | 56 | 1.5 | 35 | 1.9 | 35 | 2.2 | 35 | APCS-35 | 77 |

| ICB200 | CAD | 200 | 45 | 35 | 80 | 1.5 | 50 | 1.9 | 50 | 2.2 | 50 | APCS-35 | 77 |

| ICB250 | CAD | 250 | 45 | 48 | 72 | 1.5 | 66 | 1.9 | 66 | 2.2 | 66 | APCS-48 | 110 |

| ICB350 | CAD | 350 | 45 | 48 | 85 | 1.5 | 77 | 1.9 | 77 | 2.2 | 89 | APCS-48 | 110 |

| ICB500 | CAD | 500 | 45 | 48 | 105 | 1.5 | 125 | 1.9 | 125 | 2.2 | 46 | APCS-48 | 110 |

FAQs

Curious about Assmann storage solutions? Listed below are the most common questions about our Conical Bottom Storage Tanks. If you have additional questions about your next polyethylene storage tank, contact our experts.

What's the under clearance from the Cone Tip?

Assmann Conical Bottom Storage Tanks come standard with 14” of under clearance from the floor to the cone tip. This height can be adjusted by contacting us to order a custom configuration for your conical tank stand. Regardless of your storage need, it’s important to maintain space beneath the tank to allow for pipes, valves, and the tank connection.

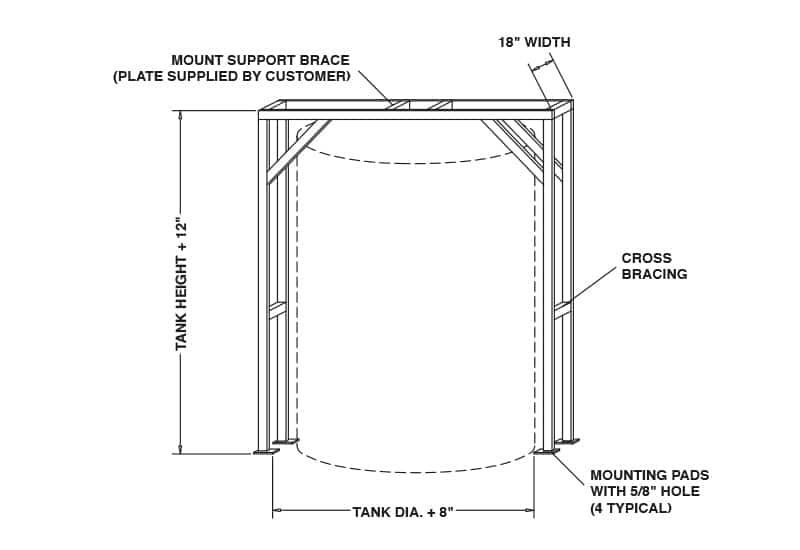

Can I build my own tank stand?

We do not recommend that you build your own conical stands. Our conical tank stands have a full pan design, with the cone tip completely supported by metallic sheeting material. In contrast, competitor designs use rods that run every 12 or 18 inches, which can cause the cone tip to sag through the frame.

What are the benefits of a full-pan design conical stand?

Allowing the polyethylene cone tip to sag and bulge through the framework can significantly reduce the lifespan of the tank and even cause tank failure. That’s why we choose the full-pan fully supported design.

Related Accessories

Preserve the life and efficiency of your tank with accessories customized to your specific tank.

Agitator Support Brackets

Self-supporting agitator support brackets are designed to handle mixers with horse power ratings of 3 or 5 HP. Agitator support stands are made from mild steel and are epoxy painted as a standard.

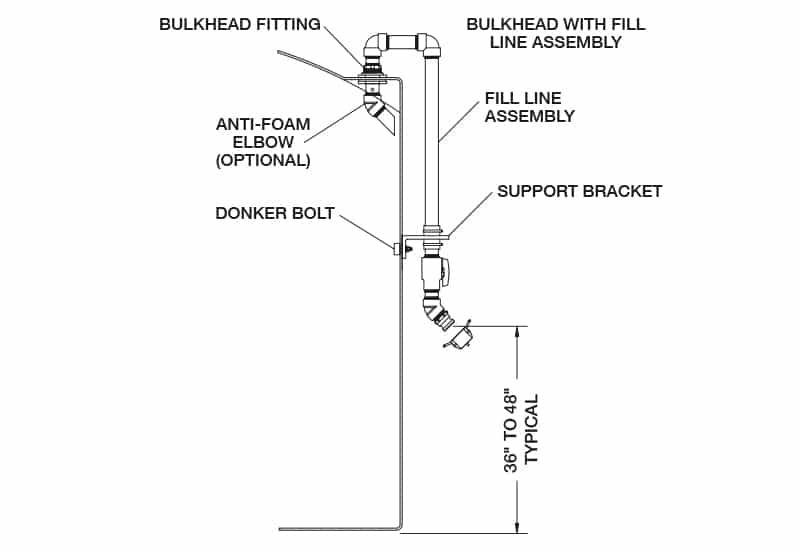

Fill Line Assemblies

These assemblies make it possible to fill the plastic storage tank from a convenient position outside the tank.

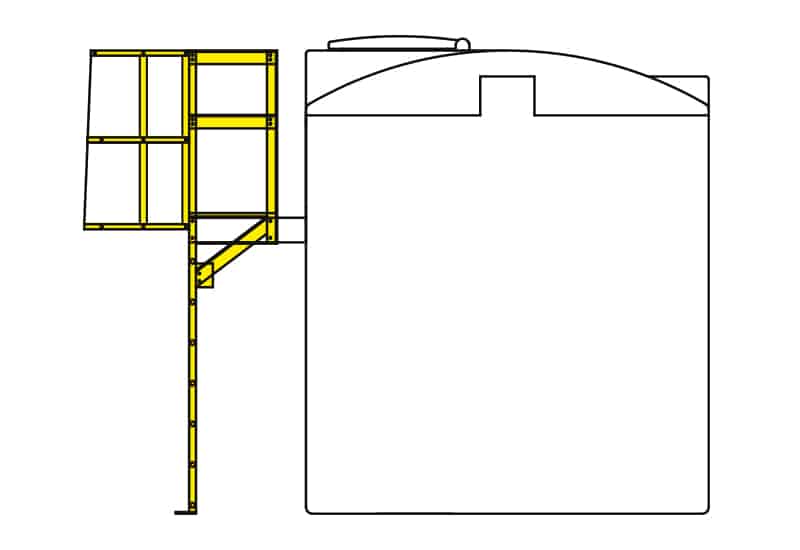

Fiber Reinforced Ladder Assemblies

Ladder assemblies are available in three configurations: platform, straight ladder with cage, and ladder with cage and platform.

Ready to bring Assmann products to your line of work?

Request a quote now.

Chemical Resistant Data

Maintain safety and efficiency with Assmann’s chemical resistant data chart.